Views: 0 Author: Site Editor Publish Time: 2023-11-22 Origin: Site

Heavy duty bar grating is a versatile and efficient solution that plays a crucial role in enhancing the structural integrity of various industrial applications. With its exceptional strength and durability, heavy duty bar grating provides a reliable platform for heavy loads, ensuring safety and stability in demanding environments.

One of the key benefits of heavy duty bar grating is its ability to support heavy loads without compromising on safety. This type of grating is specifically designed to withstand the weight of heavy machinery, equipment, and personnel, making it an ideal choice for industries such as manufacturing, oil and gas, mining, and transportation. By distributing the weight evenly across its bars, heavy duty bar grating minimizes the risk of structural failure and ensures a secure working environment.

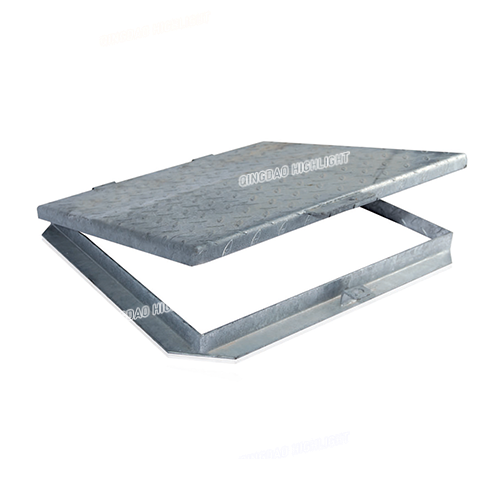

Moreover, heavy duty bar grating finds extensive applications in various industries due to its versatility. From walkways and platforms to stair treads and trench covers, this type of grating can be customized to suit different needs and specifications. Its open design allows for easy drainage of liquids, preventing the accumulation of water or other substances that could pose a safety hazard. Additionally, heavy duty bar grating provides excellent ventilation, reducing the risk of heat build-up and improving air circulation in industrial settings.

When it comes to installation and maintenance, heavy duty bar grating offers convenience and cost-effectiveness. Its modular construction allows for quick and easy installation, saving both time and labor. The grating can be easily secured to existing structures or used to create new platforms and walkways. Maintenance is also simplified, as heavy duty bar grating is resistant to corrosion, rust, and wear, ensuring a longer service life with minimal upkeep.

In conclusion, heavy duty bar grating is an essential component for enhancing the structural integrity of industrial applications. Its benefits, including its ability to support heavy loads, versatility in various industries, and ease of installation and maintenance, make it a valuable investment for any business looking to ensure safety and durability in their operations.

Heavy duty bar grating is a versatile and highly durable type of grating that offers a range of benefits in various industries. This type of grating is made from sturdy materials such as steel or aluminum, making it capable of withstanding heavy loads and harsh environments. Its unique design consists of interlocking bars that provide strength, stability, and a high level of safety.

One of the main benefits of heavy duty bar grating is its strength and durability. It is designed to support heavy loads, making it ideal for applications where there is a need for a strong and reliable flooring solution. Whether it is used in industrial plants, warehouses, or outdoor areas, heavy duty bar grating can withstand the weight of heavy machinery, equipment, and vehicles without compromising its integrity.

Another advantage of heavy duty bar grating is its versatility. It can be customized to meet specific requirements, including different bar sizes, spacing, and surface finishes. This allows it to be used in various applications, such as catwalks, platforms, stair treads, trench covers, and mezzanine flooring. Additionally, heavy duty bar grating can be easily cut and shaped to fit different layouts, making it suitable for both new installations and retrofits.

In addition to its strength and versatility, heavy duty bar grating also offers excellent drainage and ventilation properties. Its open design allows for the passage of air, water, and light, reducing the risk of moisture buildup, corrosion, and mold growth. This makes it particularly beneficial in environments where there is a need for proper airflow and drainage, such as wastewater treatment plants, food processing facilities, and outdoor areas subjected to rain or snow.

Furthermore, heavy duty bar grating is a cost-effective solution. Its durable construction ensures a longer lifespan compared to other types of flooring, reducing the need for frequent replacements or repairs. Its low maintenance requirements also contribute to its cost-effectiveness, making it an attractive option for businesses looking to minimize long-term expenses.

Heavy duty bar grating is a versatile and essential component in various applications. Its strength and durability make it suitable for a wide range of industries, including construction, manufacturing, and transportation. This type of grating is commonly used in environments where heavy loads and high traffic are present.

One of the primary applications of heavy duty bar grating is in industrial flooring. Its robust construction allows it to withstand heavy equipment, machinery, and vehicle traffic. This makes it an ideal choice for factories, warehouses, and manufacturing plants. Heavy duty bar grating provides a stable and secure surface that enhances worker safety and productivity.

Another important application of heavy duty bar grating is in the construction industry. It is commonly used as walkways, platforms, and stair treads in construction sites. The grating's strength and anti-slip properties make it a reliable choice for ensuring worker safety in hazardous environments. Additionally, heavy duty bar grating can be customized to fit specific architectural requirements, providing both functionality and aesthetic appeal.

Transportation infrastructure also benefits from the applications of heavy duty bar grating. It is frequently used in bridge decks, highway overpasses, and airport runways. The grating's high load-bearing capacity and corrosion resistance make it suitable for withstanding heavy traffic and harsh weather conditions. Heavy duty bar grating ensures the structural integrity of these critical transportation routes, promoting safe and efficient travel.

Furthermore, heavy duty bar grating finds applications in the energy sector. It is commonly used in power plants, oil refineries, and offshore drilling platforms. The grating's ability to withstand extreme temperatures, corrosive substances, and heavy loads makes it an essential component in these demanding environments. Heavy duty bar grating provides a reliable platform for workers to access equipment and perform necessary maintenance tasks.

Heavy duty bar grating is an essential component in various industries, providing strength, durability, and safety in industrial facilities. Whether it's used for walkways, platforms, trenches, or stair treads, proper installation and maintenance are crucial to ensure its long-lasting performance. In this article, we will delve into the key aspects of installing and maintaining heavy duty bar grating.

During the installation process, it is important to have a clear understanding of the project requirements and specifications. The first step is to determine the correct size and type of heavy duty bar grating needed for the application. Factors such as load capacity, span, and frequency of use should be taken into consideration to ensure the grating can withstand the intended usage.

Once the appropriate heavy duty bar grating is selected, the next step is to prepare the installation site. The area should be cleared of any debris or obstacles that may hinder the installation process. It is crucial to ensure a level and stable foundation to provide optimum support for the grating. Proper alignment and spacing of the grating panels are essential to avoid any gaps or misalignments that could compromise its structural integrity.

During the installation, it is important to use the appropriate fasteners and clips to secure the heavy duty bar grating in place. These fasteners should be corrosion-resistant and capable of withstanding the load requirements. It is recommended to follow the manufacturer's guidelines and recommendations for the installation process to ensure a secure and stable structure.

Maintenance is a crucial aspect of prolonging the lifespan and performance of heavy duty bar grating. Regular inspections should be conducted to identify any signs of wear, damage, or corrosion. Any loose or damaged grating panels should be replaced promptly to prevent accidents or further deterioration.

Cleaning the heavy duty bar grating regularly is essential to remove any dirt, debris, or contaminants that may accumulate over time. Depending on the environment and usage, different cleaning methods can be employed, such as brushing, pressure washing, or using mild detergents. It is important to avoid abrasive cleaning materials or chemicals that may cause damage to the grating surface.

Additionally, applying a protective coating or paint to the heavy duty bar grating can help enhance its resistance to corrosion and prolong its lifespan. The choice of coating or paint should be compatible with the grating material and the specific environment it will be exposed to.

Heavy duty bar grating is a strong, durable, and versatile flooring solution that offers numerous benefits. It can support heavy loads, provide excellent drainage and ventilation, and withstand harsh conditions, making it ideal for various industries and outdoor environments. Its strength, durability, and versatility make it suitable for industrial flooring, construction projects, transportation infrastructure, and energy facilities. Proper installation, regular inspections, and effective maintenance strategies are essential for ensuring the safety and reliability of heavy duty bar grating in different industrial applications.