Steel Grating:

Versatile Solutions for Industrial and Architectural Applications

How Is Steel Grating Made ?

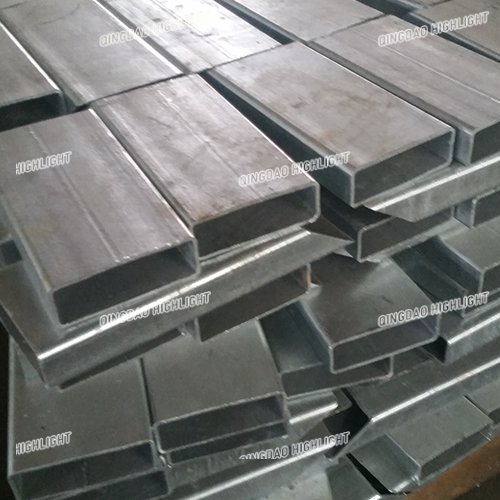

Steel grating is a versatile material made from a grid of bars or slats that are welded or molded into a frame. The process of making steel grating involves several key steps that contribute to its strength, durability, and suitability for various applications.

Types of Steel Grating

Our steel grating products are categorized to meet diverse industrial and architectural needs:

Four Key Applications of Steel Grating

Industrial Platforms

Steel grating is widely used in industrial platforms and walkways, providing strong support and a safe walking surface. Its anti-slip properties ensure stability for workers in slippery environments, making it common in factories, warehouses, and energy plants in heavy industries.

Drainage Systems

Steel grating is often employed in drainage and sewer systems, where it serves as a cover for channels and pits. The material’s open mesh structure allows water to pass through freely while preventing debris from obstructing the flow. It is widely used in urban infrastructure, roadways, parking lots, and industrial facilities to manage stormwater and wastewater efficiently.

Ventilation and Access

In ventilation and access applications, steel grating is used for creating covers that allow for air circulation while providing secure access points for maintenance. It is commonly found in underground utilities, air vents, and maintenance shafts. The grating’s design ensures sufficient airflow while maintaining structural integrity and safety in commercial and industrial buildings.

Transportation Infrastructure

Steel grating plays a critical role in transportation infrastructure, including pedestrian walkways, bridge decks, and drainage systems on highways. Its ability to withstand heavy vehicle loads and environmental stress makes it an ideal choice for public transportation hubs and road systems. The material is also used for creating safe walking paths for pedestrians while facilitating efficient water drainage.

Product Advantages

High Load-Bearing Capacity

Steel grating is known for its exceptional load-bearing capacity, making it ideal for use in heavy-duty industrial applications. It can support the weight of heavy machinery, vehicles, and large foot traffic without compromising its structural integrity. This makes it a reliable choice for industrial platforms, walkways, and loading docks, where durability and safety are paramount. Its strength ensures long-term performance even under extreme conditions, reducing the need for frequent replacements.

Corrosion Resistance

One of the key advantages of steel grating is its resistance to corrosion, especially when treated with processes such as hot-dip galvanizing. This makes steel grating suitable for use in harsh environments like chemical plants, marine areas, and outdoor applications. The corrosion resistance ensures that the grating maintains its structural strength and appearance over time, even when exposed to moisture, chemicals, and other corrosive elements. This durability helps reduce maintenance costs and extends the life of the product.

Versatility and Customization

Steel grating is available in a wide variety of types, such as Aluminum Grating, Serrated Steel Grating, and Platform Grating, allowing it to be customized to suit specific applications. Whether you need a lightweight solution for outdoor spaces or a heavy-duty grating for industrial settings, steel grating offers flexibility in design and application. It can be manufactured in various sizes, shapes, and finishes to meet the unique needs of different industries, from construction and manufacturing to infrastructure and transportation.

FAQs

Q: What is the difference between serrated and plain steel grating?

A: Serrated steel grating features a surface with serrated (tooth-like) edges, providing enhanced slip resistance. This is particularly useful in wet or oily environments where safety is a concern, such as in chemical plants, walkways, or offshore platforms. Plain steel grating, on the other hand, has a smooth surface without the added texture, making it suitable for applications where slip resistance is not a critical factor. Both types offer high strength and durability but are chosen based on the specific needs of the environment.

Q: Can steel grating be used for both indoor and outdoor applications?

A: Yes, steel grating is highly versatile and can be used for both indoor and outdoor applications. For outdoor environments, galvanized or stainless steel grating is often recommended due to its resistance to corrosion from exposure to moisture and chemicals. For indoor use, plain or painted steel grating may be preferred, depending on the aesthetic and load requirements. Steel grating is commonly used in platforms, walkways, drainage systems, and even architectural features in both types of settings.

Q: How do I maintain steel grating to ensure its longevity?

A: Maintaining steel grating is relatively simple, but it is essential for ensuring its longevity. Regular cleaning to remove dirt, debris, and any chemicals that could promote corrosion is important, especially in outdoor and industrial environments. For galvanized or stainless steel grating, periodic inspections for signs of wear or rust can help catch any issues early. If the grating is painted, a fresh coat of paint may be applied as needed to maintain its aesthetic appearance and prevent corrosion. Additionally, ensuring proper drainage and airflow around the grating will help prevent build-up of water or other damaging substances.

Related Blogs

Keep in touch with us

Thank you for your interest in our steel grating products. If you have any questions, require a quote, or need assistance with your project, please don't hesitate to reach out to us. Our team is ready to provide you with the information and support you need.

Mob:+86-13583288069

E-mail:albertqdsd@cnmgss.com