Views: 0 Author: Site Editor Publish Time: 2024-11-08 Origin: Site

Steel grating is a flexible and widely involved item in various enterprises,from improvement to assembling.The sort of metal utilized for grating plays out a basic situation in recognizing its presentation,strength,and reasonableness for remarkable applications.In this complete article,we will discover the quite a number kinds of metal used for grating,such as the famous swaged grating,and talk about the elements to reflect onconsideration on when deciding on the proper metal for your grating needs.

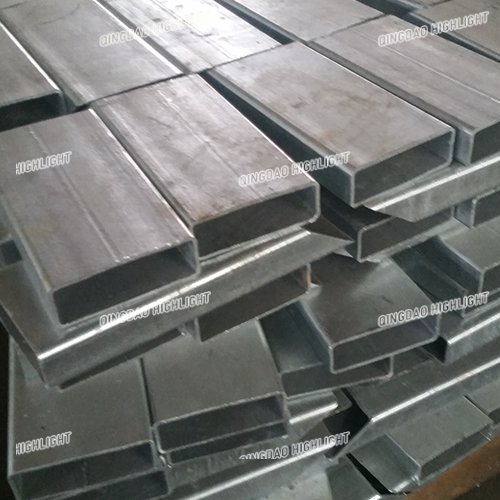

1、Carbon Steel

Carbon metal is the most generally used fabric for metal grating due to its superb strength-to-weight ratio and cost-effectiveness.It is accessible in exceptional grades,with various carbon content,which influences its properties:

Gentle Steel:Contains 0.05%to 0.25%carbon,giving astounding formability and weldability.

Medium Carbon Steel:Contains 0.30%to 0.60%carbon,giving a dauntlessness among power and pliability.

High Carbon Steel:Contains 0.60%to 1.00%carbon,giving unbalanced power and put on obstruction.

Carbon steel gratings,which comprises of swaged grinding,are frequently utilized in modern deck,walkways,and structures the area unbalanced energy is required.

2、Stainless Steel

Stainless steel grating is preferred in environments the place corrosion resistance is paramount.The addition of chromium(at least 10.5%)creates a shielding layer that prevents rust and corrosion.Common sorts of stainless steel used for grating include:

Type 304:Offers magnificent corrosion resistance and is terrific for most environments.

Type 316:Provides most efficient corrosion resistance,in specific in marine and chemical processing applications.

Stainless steel grating is regularly used in meal processing plants,pharmaceutical facilities,and offshore structures.

3、Aluminum

While now not technically steel,aluminum grating is really worth citing as it is regularly used as a choice of metal grating in certain applications.Aluminum offers:

Lightweight construction

Natural corrosion resistance

Non-sparking properties

Aluminum grating is regularly used in marine environments,architectural applications,and areas the place weight is a concern.

4、Galvanized Steel

Galvanized metal grating is created by way of coating carbon metal with a layer of zinc.This manner provides:

Enhanced corrosion resistance

Extended lifespan in outside environments

Cost-effective choice of stainless metal for some applications

Galvanized metal grating,inclusive of swaged grating versions,is regularly used in out of outdoors walkways,parking structures,and industrial facilities.

1、Load-Bearing Capacity

The power of the metal is fundamental in identifying the load-bearing potential of the grating.Factors to think about include:

Expected stay loads

Static loads

Impact loads

Swaged grating,for example,regularly provides ultimate load-bearing capability due to its special manufacturing process.

2、Corrosion Resistance

The surroundings in which the grating will be set up perform a huge function in cloth selection:

Indoor,dry environments may additionally solely require carbon steel

Outdoor or humid environments would possibly need galvanized or stainless steel

Chemical publicity may also necessitate high-grade stainless metal or specialised coatings

3、Maintenance Requirements

Different kinds of metal grating require various ranges of maintenance:

Stainless metal grating usually requires minimal maintenance

Carbon metal can also want everyday portray or coating to forestall rust

Galvanized metal provides a top stability of corrosion resistance and low maintenance

4、Cost Considerations

Budget regularly performs a critical function in fabric selection:

Carbon metal is usually the most low-priced option

Stainless steel,whilst greater high-priced upfront,may additionally provide long-term fee financial savings in corrosive environments

Galvanized metal gives a middle-ground option

5、Aesthetics

In some applications,the appearance of the grating is important:

Stainless metal gives a modern,smooth look

Painted carbon metal can be personalized into shape unique colour schemes

Swaged grating regularly presents a unique,industrial aesthetic

6、Specific Industry Requirements

Certain industries have particular necessities for grating materials:

Food processing industries regularly require stainless metal for hygiene reasons

Offshore oil and fuel structures can also require specialised corrosion-resistant alloys

Architectural functions would possibly prioritize aesthetics and light-weight materials

7、Applications of Steel Grating

Steel grating,consisting of swaged grating,finds functions throughout a broad range of industries and settings:

Industrial Flooring

Steel grating is drastically used in manufacturing plants,warehouses,and processing services for:

Mezzanine floors

Catwalks

8、Equipment platforms

The excessive energy and open layout of metal grating permit for environment friendly load distribution and handy cleaning.

Construction and Architecture

In the development industry,metal grating is used for:

Walkways and bridges

Stair treads

Security fencing

Decorative factors in current architecture

9、Transportation Infrastructure

Steel grating performs an essential function in transportation systems:

Bridge decking

Railway platforms

Airport walkways

Parking structures

10、Marine and Offshore Applications

Corrosion-resistant metal grating,regularly stainless metal or hot-dip galvanized,is critical in:

Offshore oil and gasoline platforms

Ship decks and gangways

Marina walkways and docks

In conclusion,the desire of metal for grating relies upon on a complicated interaction of elements consisting of the unique application,environmental conditions,load requirements,and price range constraints.From carbon metal to stainless steel,and specialised preferences like swaged grating,every kind affords special advantages.By cautiously thinking about these elements and appreciating the quite a number metal alternatives available,engineers and task managers can pick out the most fabulous grating fabric for their particular needs,making sure highest quality performance,longevity,and cost-effectiveness in their projects.

As the demand for durable,high-performance development substances continues to grow,improvements in metal grating,such as superior swaged grating strategies and new corrosion-resistant alloys,are probable to enlarge the probabilities for this versatile product.Whether it is for industrial flooring,architectural features,or specialised purposes in harsh environments,metal grating stays an indispensable aspect in current development and engineering projects.